显示 145-156 个结果(共 157 个结果)

产品

产品类别

- Insulation tape

- Copper Foil Tape

- Crepe Masking Paper Tape

- Double side adhesive tape

- DUPONT® Polyimide Tape

- Filament Reinforced

- Glass Cloth Tape

- KAPTON® Polyimide Tape

- Nomex® Aramid Paper Tape

- PCB Tape

- PEN (Polyethylene Naphthalate) TAPE

- Polyester Knit&Cloth Tape

- Polyester Tape

- Polyimide Tape

- PPS Tape

- PTFE Cloth Tape

- PVC Tape

- Reinforced Polyester film

- 铜线

- 电源线

- Power Cable

- 电线组装

- Heating Wire

- Tubing & Sleeving

- MICA

- 柔性复合材料

- Bobbin

- UL System

- PowerEsim

按市场过滤

- 电器电器 137

- 交通交通 137

- ElectronicsElectronics 106

- 工业工业 137

- LightingLighting 106

- 医疗医疗 134

- Medical eletronicsMedical eletronics 3

FILTER BY APPLICATION

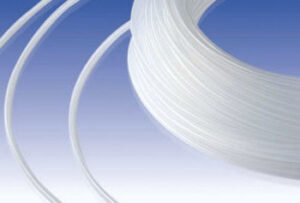

PTFE TUBE

UL Recognized Extruded Tubing, Electrical (YDPU2) UL File No. E176865

BCTube® 在超净室中采用 PTFE 挤出工艺制造。 PTFE具有优异的耐化学性、耐热性、耐候性以及良好的电性能。 强烈推荐用于半导体和变压器行业。

P.Leo is committed to manufacturing and distributing the best quality tubing to her customers worldwide. We strive to achieve maximum customer satisfaction by providing quality products at reasonable prices.

PVC Tape

A plasticized polyvinyl chloride(PVC) film, giving excellent conformability and flexibility, coated with an aggressive Rubber-Resin adhesive with good ageing

characteristics. No flagging or deterior ation even under temperature as high as 80oC.Flame retardant, cold and weather resistant. UL listed and CSA certified. For use as electrical insulation onjoints and splices in wires and cables in accordance with the National Electrical Code.

Reinforced Polyester film

Polyester film/mat; excellent electrical properties; tough, conformable; for insulating, anchoring and banding in motor and transformers, good for barrier tape with CTI Group 1 >600V .

(Mark with “*” refers to accord with the requirement of halogen free).

Silicone Rubber Coated Fiberglass Sleeving

Halogen Free Heat Shrinkable Tube is newly developed environmental-friendly flame retardant heat shrinkable tube, using specially designed formulation of high polymers, through cross-link by electric accelerator and continuous expansion. The properties of environment-friendly, flexibility flame retardant, quick shrink and stable performance make them widely used in the field of electronics, communication, automobile, and widely applied for connecting or end-handing, electric wire, insulating and harness of electric wire corrosion and rust –proof of metallic rods or tubes, antenna protection and marking for other products.

Simple Wiring Assembly

In a world of intricate designs, we’re taking a moment to embrace simplicity with our latest endeavour.

A lead wire UL1007 crimped with 187 series female terminal and coverage by heat shrink tube.

This showcases a different side to our manufacturing capability. While our expertise usually shines in crafting complex cable assemblies, this time we’re celebrating the elegance of minimalism.

This simple cable assembly proves that sometimes, all you need is a couple of reliable wires to bridge connections and create magic.

Sleeving

Silicone rubber coated fiberglass sleeving UL File No. E195829

Electrical Insulating Sleeving for :

(1)High & Low Temperature Applications.

(2)High & Low Voltage Applications.

(3)Abrasive & Other Physically Demanding Applications.

(4)Flame Resistance.

(5)UL requirements.

(6)Compatibility with Polyester, Acrylic, Epoxy, Phenolic, Fomvar & Other Wire Enamels.

Spiralled Fluorine Heating Wire

Similar in structure of our spiralled PVC heating wire, our spiralled fluorine heating wire is specially design in area where high temperature and rapid heating is required. To overcome the harsh heating environment, our spiralled fluorine heating wire offers a high range engineer fluorine polymer, custom made for your need.

Spiralled PVC Heating Wire

Our dual layers heating wire provides a cost effective, while safe heating solution to low wattage applications where comfort and flexibility are important. With one spiral layer acts as a heating element, the other spiral layer simultaneously detects the temperature, our spiralled heating wire packs a lot in one small wire. To add on to this, the PVC mid-insulation acts as a fail-safe which prevent the wire from overheating.

Tin-plated Wire

ROBUST PROTECTION AGAINST CORROSION AND OXIDATION

Corrosion resistance and easy to solder

Tin-plated wire is an uninsulated wire that is coated by a layer of tin. Bare copper wire is prone to oxidation over time compared with tin-plated wire. The tin coating protects wire from oxidation in humid and rainy conditions, and high heat environments. Tin-plated wire will be ideal in environments with long-term exposure to excess moisture to prolong the lifespan of copper conductors.

Triple Insulated Wire

VERY HIGH DIELECTRIC STRENGTH AND BREAKDOWN VOLTAGE

THL-B series

THL-B series, thermal class at 130°C, is a unique product for high frequency transformers. Three layer extruded coatings of high performance polymer resins gives excellent dielectric properties to this type of winding wires. Unlike enameled wires, three layers of insulation are extruded over the copper conductor with automated manufacturing process, to ensure perfect central position of conductor.

The conventional enameled wire winding coils requires insulation between the primary and secondary coils by means of barrier tape or interlayer tape to isolate primary and secondary windings. Since three layers coating is having very high dielectric strength, it has very less creepage factor. This positive feature of THL serves to downsize switching transformers and promises high production efficiency and cost reduction. Depending on the design, the transformer size can be reduced up to 40% and weight up to 60% as compared to transformers made of enameled wires.

Triple Insulated Wire THL-F series

VERY HIGH DIELECTRIC STRENGTH AND BREAKDOWN VOLTAGE

THL-F series

THL-F series, thermal class at 155°C, is a unique product for high frequency transformers. Three layer extruded coatings of high performance polymer resins gives excellent dielectric properties to this type of winding wires. Unlike enameled wires, three layers of insulation are extruded over the copper conductor with automated manufacturing process, to ensure perfect central position of conductor.

The conventional enameled wire winding coils requires insulation between the primary and secondary coils by means of barrier tape or interlayer tape to isolate primary and secondary windings. Since three layers coating is having very high dielectric strength, it has very less creepage factor. This positive feature of THL serves to downsize switching transformers and promises high production efficiency and cost reduction. Depending on the design, the transformer size can be reduced up to 40% and weight up to 60% as compared to transformers made of enameled wires.

Triple Insulated Wire THL-H series

VERY HIGH DIELECTRIC STRENGTH AND BREAKDOWN VOLTAGE

THL-H series

THL-H series, thermal class at 180°C, is a unique product for high frequency transformers. Three layer extruded coatings of high performance polymer resins gives excellent dielectric properties to this type of winding wires. Unlike enameled wires, three layers of insulation are extruded over the copper conductor with automated manufacturing process, to ensure perfect central position of conductor.

The conventional enameled wire winding coils requires insulation between the primary and secondary coils by means of barrier tape or interlayer tape to isolate primary and secondary windings. Since three layers coating is having very high dielectric strength, it has very less creepage factor. This positive feature of THL serves to downsize switching transformers and promises high production efficiency and cost reduction. Depending on the design, the transformer size can be reduced up to 40% and weight up to 60% as compared to transformers made of enameled wires.